Specialist Lift Maintenance Repair for Residential and Commercial Lifts

Specialist Lift Maintenance Repair for Residential and Commercial Lifts

Blog Article

Pro Tips for Maintaining Your Lift in Top Problem: A Thorough Summary

Making sure the ideal performance of a lift system is imperative for a safe and efficient procedure in numerous setups, from industrial storage facilities to industrial buildings. By adhering to a structured maintenance regimen and preemptively addressing possible issues, lift proprietors can minimize pricey downtime and safety and security hazards.

Significance of Normal Maintenance

Routine upkeep of your lift is important to guarantee its optimal efficiency and long life. By adhering to a routine upkeep schedule, you can recognize and address prospective concerns before they intensify right into costly repairs or unanticipated downtime. Regular maintenance tasks such as lubricating relocating components, inspecting for deterioration, and examining hydraulic systems can help avoid breakdowns and ensure secure operation.

Ignoring normal upkeep not just compromises the efficiency of your lift however additionally postures safety risks to individuals and property. Components that are not properly maintained may fail unexpectedly, resulting in accidents or damage to the lift itself. Furthermore, attending to concerns at an early stage with upkeep can expand the life-span of your lift and reduce the possibility of major malfunctions.

Along with enhancing security and performance, normal upkeep can likewise save you cash over time. By spending in precautionary maintenance measures, you can stay clear of expensive repair work or replacements that might develop from overlooking the upkeep of your lift. On the whole, focusing on routine maintenance is vital for making best use of the capability and long life of your lift system.

Top Components to Evaluate

In addition, pay very close attention to the lift's safety and security attributes, such as emergency situation stop switches, safety and security sensing units, and interlocking mechanisms, to guarantee they are working properly. Routinely inspect the lift shaft for particles or blockages that might impede the activity of the lift automobile. Lastly, do not fail to remember to analyze the doors, hinges, and door drivers to ensure smooth opening and closing operations. By meticulously inspecting these leading elements, you can catch possible problems early and ensure your lift continues to be in leading condition.

Aggressive Troubleshooting Methods

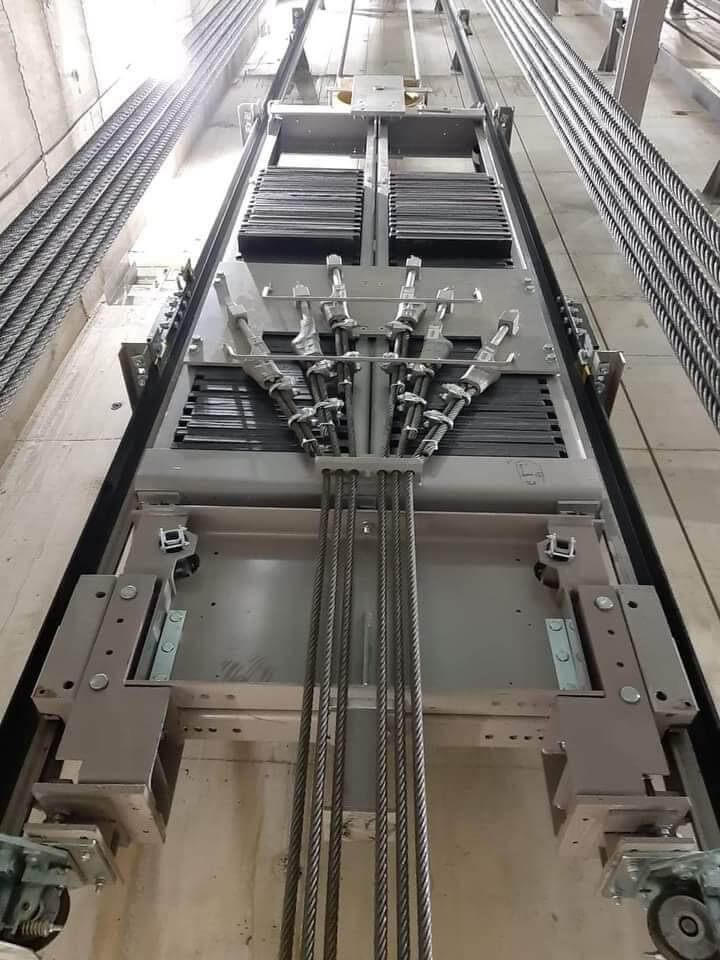

When faced with prospective lift system problems, adopting proactive fixing strategies can considerably improve functional efficiency and stop pricey downtime. One of the essential aggressive troubleshooting techniques is to on a regular basis monitor and examine lift efficiency information. By tracking metrics such as lift speed, electric motor temperature, and energy consumption, upkeep groups can recognize very early indicators of potential issues and take corrective actions prior to they rise. Performing regular aesthetic examinations of crucial components, such as cable televisions, sheaves, and security mechanisms, can also help in discovering deterioration or imbalances that might cause malfunctions. Furthermore, executing a preventive maintenance schedule that consists of lubrication of moving components, screening of emergency brakes, and calibration of sensors can proactively address usual lift system issues.

Additionally, buying training programs for upkeep staff on repairing methods specific to the lift design installed can equip them to diagnose and solve issues promptly. By staying in advance of possible problems via proactive troubleshooting, lift drivers can ensure a smoother and a lot more dependable procedure while minimizing the danger of unanticipated break downs.

Necessary Lubrication Practices

Executing correct lubrication practices is vital for ensuring the smooth operation and durability of lift systems. Normal lubrication helps minimize rubbing between moving parts, protecting against deterioration that can result in costly repair services and downtime. When it comes to lift maintenance, following a stringent lubrication routine is essential.

Choosing the best lubricant is the very first step in effective upkeep. Different parts of the lift system might need specific kinds of lubes, such as oil or oil. Consult the supplier's standards to identify the appropriate lubricants for each part.

On a regular basis evaluating the condition of lubricated parts is also essential. Try to find indicators of too much wear, contamination, or inadequate lubrication. Address any type of problems without delay to protect against more damages and ensure the ongoing smooth operation of your lift system. By focusing on correct lubrication techniques, you can expand the life expectancy of your lift and enhance its performance.

Precaution for Lift Operators

In order to preserve a risk-free working setting and promote functional performance, lift drivers have to rigorously stick to suggested safety and security methods, together with prioritizing necessary lubrication methods for ideal lift efficiency. Precaution for lift operators are critical to stop accidents and ensure the smooth performance of the lift system. Operators ought to undertake complete training on proper lift procedure, emergency treatments, and security guidelines. Routine tools assessments and maintenance checks are essential to recognize and deal with any kind of prospective safety and security dangers promptly. It is necessary for operators to constantly adhere to producer referrals for load abilities, operational restrictions, and safety functions use.

Furthermore, lift drivers must prioritize personal safety equipment (PPE) such as safety helmets, gloves, and security harnesses when working at elevations or handling heavy tons. Clear interaction amongst operators, maintenance professionals, and various other employees is essential to stop misconceptions that can cause crashes. Finally, drivers ought to stay attentive, concentrated, and https://www.lift-maintenance-repair.co.uk/ stay clear of distractions while operating the lift to make sure the safety and security of themselves and others around.

Conclusion

In conclusion, preserving a lift in top condition is vital for guaranteeing security and effectiveness in procedures. Routine maintenance, complete assessments of essential elements, positive troubleshooting, appropriate lubrication methods, and adherence to precaution are vital for prolonging the life-span of the lift and avoiding accidents. By complying with these guidelines, lift drivers can ensure the ongoing functionality and security of their equipment.

By sticking to a structured upkeep program and preemptively addressing possible issues, lift proprietors can reduce pricey downtime and security hazards. Regularly check the lift shaft for debris or blockages that could impede the motion of the lift automobile.In order to maintain a risk-free working setting and support functional performance, lift operators must rigorously stick to suggested safety procedures, along with focusing on important lubrication methods for optimum lift efficiency. Safety procedures for lift drivers are important to protect against accidents and guarantee the smooth functioning of the lift system. Routine upkeep, comprehensive assessments of key elements, aggressive troubleshooting, proper lubrication methods, and adherence to safety and security steps are crucial for prolonging the lifespan of the lift and stopping mishaps.

Report this page